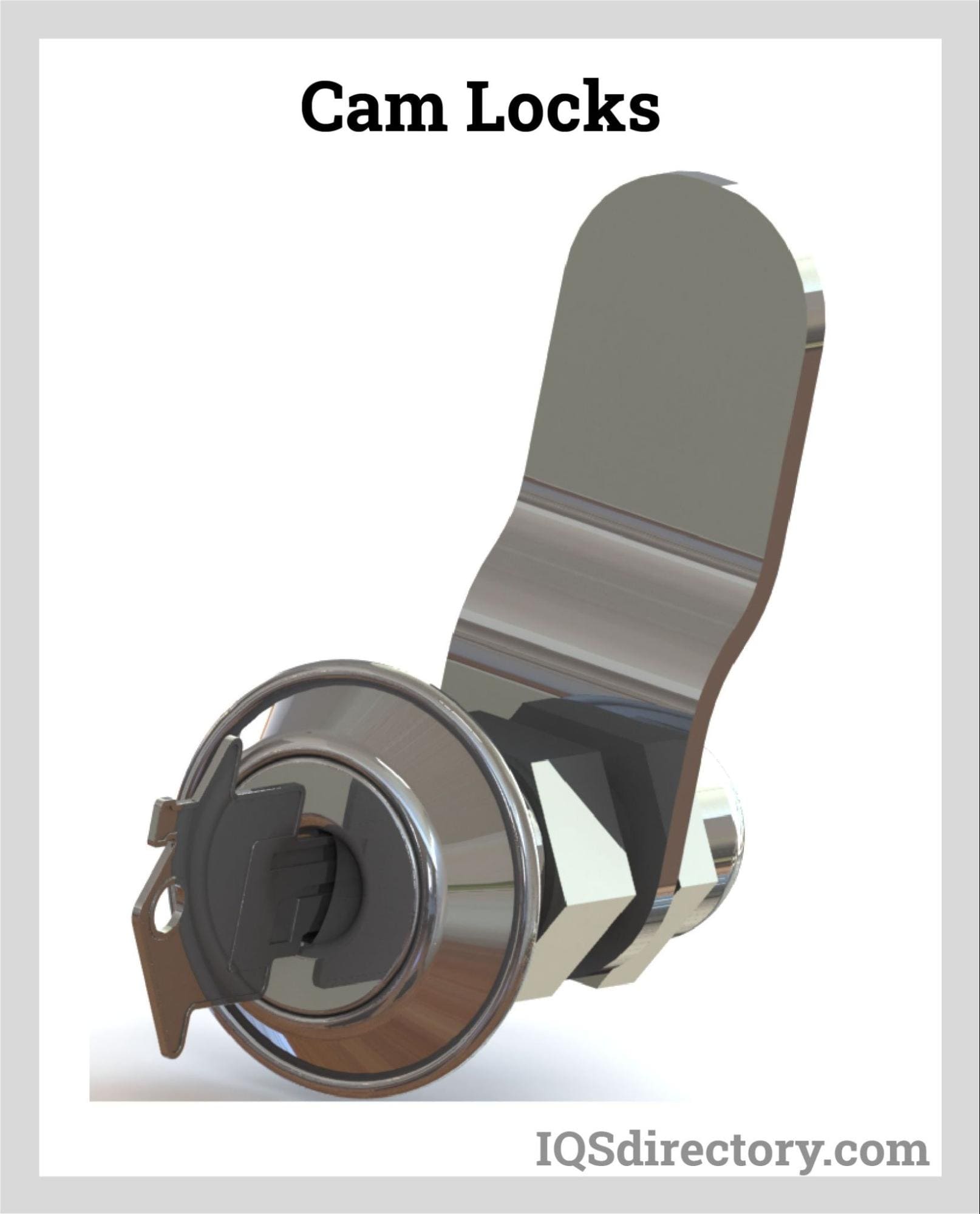

Cam locks are L-shaped locking mechanisms used to secure lockers, cabinets, and other enclosures. They are made up of a tongue bar and a cylindrical keyed nut as their major components. After installation, you can lock the enclosure by twisting the former section while inserting a key. Read More…

As an ISO certified source for industrial hardware, Sierra Pacific Engineering & Products is a company you can trust in for excellent locks. Quality, service & value are the core to being a top OEM supplier and SPEP offers a wide range of additional products.

Our specialty is custom hardware fabricated to your specifications. Our lock manufacturing capabilities include 3-slot and key locks, pad locks that are keyed solid brass, long shackle solid brass padlocks, disc padlocks, combination locks & key locks with briefcase hasp. Quality locks since 1925! We care about offering our customers quality products & service. Visit our website or call us today!

At Ranger Lock, we’ve been committed to creating more secure locks and lock guards since we opened the doors to our company all the way back in 2002. One of our most popular products, the ATF-Compliant Lock Box, is consistently a best-seller from the Ranger Lock online store due to its rugged construction and durability. When you need a fully ATF-compliant lock guard, you need the Ranger Lock...

Mul-T Lock is known as a worldwide leader in the lock manufacturing industry. We pride ourselves on being leading innovators of lock manufacturing with our state-of-the-art technologies and customized equipment. We are ISO 9001 2000 and ISO 14001 certified.

More Cam Lock Manufacturers

How Cam Locks Function

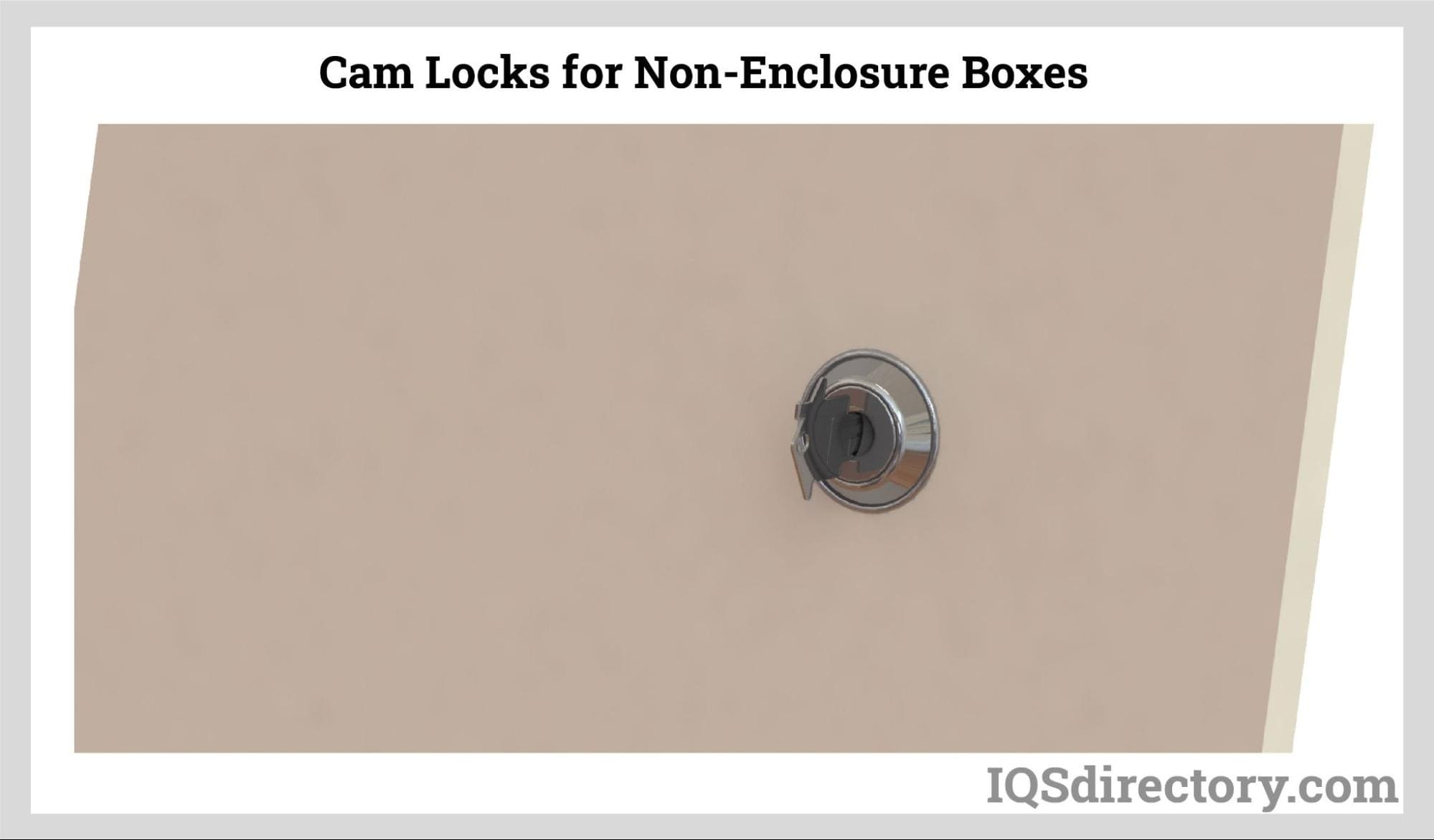

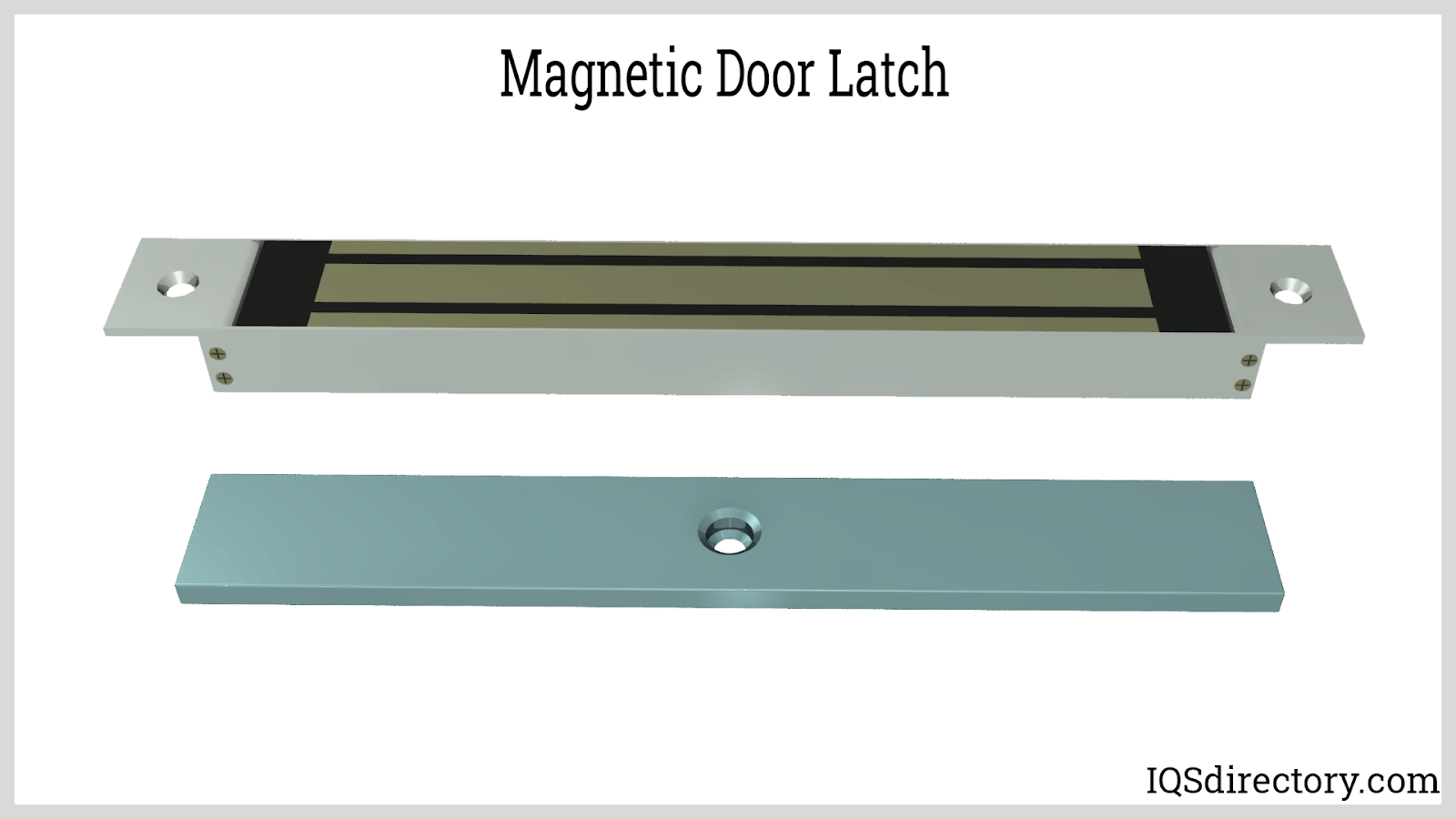

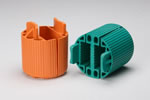

Cam locks come in various varieties, but they all function similarly. Directly within the front of an enclosure are positioned cam locks. When installed, the front of the cam lock must remain flush with the front of the enclosure.

Cam locks need to be locked and unlocked with a key. The position of the tongue bar will change when a key is inserted into a cam lock and turned. The tongue bar will move in one of two directions when the key is turned- sideways or vertically. The tongue bar will lock the enclosure when tipped to one side. Conversely, when the tongue bar is vertical.

How Cam Locks are Made

Volker Guelck, a Canadian inventor, came up with the cam lock in 1985. For cabinet drawers, safety boxes, lockers, doors, windows, and many more compartments, cam locks serve as quick and simple security systems. Rather than oscillating like a piston, a cam lock is a form of a latch with a bolt, sometimes known as a "cam," that spins around a rotation axis going through one end of the cam. Usually, a rotating plug, like a screw, is directly attached to a cam through the rotation axis. A cam lock can also be adjusted by turning a lever to pinch a door, window, or cabinet panel to its frame.

What to Consider When Selecting Cam Locks

Different materials are used to make various cam locks. A common material used to create cam locks is zinc alloy. Any metallic substance that contains zinc and at least one other metal is known as a "zinc alloy." For instance, brass, a zinc alloy, is frequently utilized in manufacturing cam locks. Consider having them keyed alike if you intend to purchase several cam locks. "Keyed alike" refers to cam locks that all operate with the same key. You won't need to manage numerous keys, whether you get six cam locks or one hundred. All cam locks can be locked and unlocked with the same key.

Cam Lock Applications

Every industry typically uses cam locks, including manufacturing, agricultural, oil, gas, chemical, pharmaceuticals, and military applications. This pairing is incredibly adaptable. Since it doesn't use threads, there are no concerns about it getting soiled or breaking. Cam lock couplings are ideal for soiled situations as a result. In addition, these couplings are ideally suited for applications where regular hose replacements are necessary, such as industrial chemical and petroleum vehicles, used on tanks that contain liquids and powders, as well as with pumps, hoses, tubing, and tanks.

Used in practically every industry where the transportation of liquids and powders is necessary, including those that deal with fuel and oil, water, chemicals, paints and dyes, food and beverage, adhesives, pharmaceuticals, cleaning supplies, and agriculture.

Materials to Consider When Choosing a Cam Lock

Stainless Steel

In extremely corrosive environments, stainless steel is the best material to use. An inner wall of a stainless steel cam lock coupling will be clean, preventing impurities, condensation, bacterial growth, the formation of strange smells, and media pollution. Stainless steel has excellent temperature resistance; it can operate safely between extreme temperatures (-30°C and 230°C) for an extended time. For specialized jobs where pipes may move or require more strength, it's a stronger, more resilient solution. It naturally resists corrosion and requires little upkeep.

Bronze

For water or waste in corrosive situations like those near salt water in the ocean or where the couplings must be non-sparking, like in marine fuel applications, choose bronze cam locks, one of the oldest alloys. Additionally, it can be employed in shipbuilding and deep-well operations.

Aluminum

Utilize aluminum cam locks in low-demand fluids, including fresh water and oil-water mixtures. It has good plasticity and can be treated in a variety of profiles. It is also a superior thermal and electrical conductor. It is typically less expensive and resistant to corrosion.

Types of Cam Locks

- Type A – male adaptor with female NPT thread

- Type B – female cam coupler with male NPT thread

- Type C – female cam coupling with hose barb end

- Type D – female cam coupler with FNPT thread

- Type E – cam adaptor with hose barb end

- Type F – cam lock adaptor with male NPT thread

- Type DC – dust caps for male adaptors

- Type DP – dust plugs for female couplers

- Safety Locks for Cam Lock Couplings: Using safety locks will prevent accidental opening of cam lock arms. They are an affordable alternative to more expensive locking handles, and they are also simple to set up and take down.

- Cam Lock Coupling Chains: These chains can join a type B, C, or D coupling or plug with a type DP dust plug or DC-type dust cap.

Safety & Preventative Maintenance for Cam Locks

A regular maintenance program that enables you to check your cam lock couplings frequently is recommended. As moving elements of cam lock couplings are prone to wear and tear, inspecting and replacing worn pieces frequently is crucial. You may increase your products’ lifespan and ensure that health and safety requirements are satisfied by replacing old parts.

Choosing the Proper Cam Lock Manufacturer

To make sure you have the most productive outcome when purchasing cam locks from cam lock manufacturers, it is important to compare at least five manufacturers using our list of cam lock manufacturers. Each cam lock manufacturer has a business profile page that highlights their areas of experience and capabilities and a contact form to directly communicate with the manufacturer for more information or request a quote. Review each cam lock company website using our patented website previewer to get an idea of what each business specializes in, and then use our simple RFQ form to contact multiple cam lock manufacturers with the same message.

Bolts

Bolts Fasteners

Fasteners Gas Spring

Gas Spring Handles

Handles Hinges

Hinges Latches

Latches Locks

Locks WIre Hooks

WIre Hooks Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services